Poly Bag Machines: The Future of Flexible Packaging in a Sustainable World

Sustainability is increasingly being prioritized today, and the world is changing in many ways. These bag making machines are known as poly bag machines, and they have changed dramatically. They allow businesses to create cost-efficient flexible packaging solutions. With the need for sustainable packaging constantly increasing, plastic bag making machines have become vital in helping firms accomplish their economic and environmental objectives. This article focuses on poly bag machines and their contribution towards a sustainable future of flexible packaging.

The Impact of Poly Bag Machines on Modern Manufacturing Processes

These machines are important components for the manufacturing of different kinds of plastic bags including single-use shopping bags and even heavy-duty industrial bags. Poly bag machines significantly automate the manual work which increases productivity, speed, and reduces the need for manpower. Plastic bag making machines are versatile because they work with various kinds of plastics like HDPE, LDPE, and LLDPE, enabling manufacturers to customize their products as needed.

The process begins when raw plastic is loaded to a machine. It is then liquefied before being extruded into a film which gets cut and sealed into a required shape. Modern technology equipped plastic bag manufacturing machines with automatic sealers and cutters for bag length as well as bag handling, resulting in higher precision and efficiency in production. Moreover, these machines are capable of printing which allows them to place logos or custom designs on the bags as they are being manufactured. With the advance of these printing technologies, the scope of usage of plastic bags is no longer restricted to just packaging and helps businesses use it for advertising and promotion purposes.

The Benefits of Using Gravure Printing Machines for Production of Plastic Bags

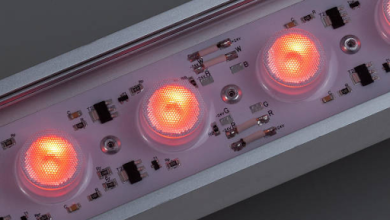

One of the most notable improvements done in the technology of making plastic bags is the use of gravure printing machines. These machines allow intricate images to be printed simultaneously on the plastic bags while they are being manufactured. Unlike Flexo printing, gravure printing provides better image quality, precision, and complex graphics due to its advanced technology.

Developments in technology have enabled manufacturers to make customized gravure printed plastic bags that represent the identity of the brand using plastic bag machines. As for the engraver’s printing machines, these can print on many base materials like the plastic films which makes them suited for plastic bags manufacturers that want to increase the value of their products. Additionally, businesses can add value and generate revenue with packages that stand out and serve the intended purpose of brand advertisement by printing images and text in order to establish higher brand awareness.

Manufacturers have adopted the integration of the gravure printing machines to plastic bag making machines as these represent high productivity machines that offer a broad range of possibilities as well as an increased production process speed. With any machine device that incorporates both devices, the production time and expense will diminish which boosts the level of efficiency within the operation. Along with this, the consistency of quality as well as the aesthetic appeal of the bags produced will surely meet the client demand.

The Effectiveness of Poly Bag Machines

Making a plastic bag is one of the most bothersome tasks for a human being, which is why it has become so popular in the packaging exercise. Automated machine for making US poly bags is substantially easier to work with than manually operated as it significantly reduces the work’s intensity and cuts down the chances of mistakes being made. Moreover, the manufacturer utilizes features such as fully automated bag handling, cut-length control, and tensioning, further enhancing the productivity of poly bags production by minimizing the amount of supervisions needed.

The use of advanced technology in plastic bag making machines also ensures the quality is well adhered to. Today’s machines that make bags can have automated processes where robot sensors are installed and are responsible for checking quantity issued, ensuring set targets in relation to correct measurements, power, strength and aesthetics are achieved, checking for breakdowns in the mechanical systems, and issues of control in order to respond quickly to necessary repairs to minimize idle times.

The other crucial efficiency gain of modern plastic bag manufacturing machines is the automation of a number of other functions, such as printing and packaging. For example, manufacturers are able to execute the gravure printing directly onto the bag so that printed bags can be made in a single operation, which saves time and lowers cost. This reduced lead time also increases flexibility with regards to the production schedule as manufacturers can now rapidly change different product configurations without having to reconstruct the machine.

How Poly Bag Machines Enhance Sustainability and Aid in Waste Reduction

The sustainability concern on the use of eco-friendly materials continues in the plastic and poly bag industry when the environmental impact of plastic waste still remains non negligible. For these reasons, governments, environmentalists, and consumers are calling for corporate social responsibility from firms in taking actions that mitigate their impact on the ecosystem. While poly bag machines are generally linked to the production of plastic packaging, they are also transforming with these challenges of sustainability by adopting changes that lessen the impact of waste and promote sustainable practices.

The production of biodegradable bags has become one of the features of modern bag making machines. These bags dissolve on their own, which helps minimize environmental damage for years to come. Along with biodegradable plastic, poly bag machines can also accept used materials, enabling producers to manufacture bags from old fashioned plastic. This change helps to lower the need for virgin plastic manufacturing. Using recycled content in packaging is one of the many vital steps in establishing a circular economy, where materials are made waste instead of being thrown away.

Responding to the needs of consumers and legislation calling for more sustainable options is what influenced the creation of sustainable material-based plastic bag making machines. These days, many businesses are investing in poly bag machines to respond to the rise in demand for eco-friendly packaging while still providing effective and durable packaging solutions.

Conclusion

Poly bag machines are essential in the evolution of flexible packaging by enabling businesses to respond at demand of consumers and environmentalists simultaneously by producing effective and high quality packaging solutions. These machines now and in the future are becoming increasingly efficient, adjustable, and eco-friendly, allowing manufacturers to meet the modern-day sustainable objectives.

With different industries now focusing on environmentally conscious sustainable practices, bag making machines are also progressing in producing packing bags that are versatile, eco-friendly, and efficient. Combining these machines with innovations such as gravure printing machines makes them more adaptable and advantageous to businesses because they enable sellers to satisfy their client’s expectations while helping sustain the environment. Flexible packaging will continue to be promising; thus, the development of poly bag machines will be essential for that progress.